The Ultimate Guide to Laser Cutter Metal: Precision, Efficiency, and Innovation

Imagine a tool that combines precision, speed, and versatility in one compact machine. That’s exactly what a laser cutter metal offers. Whether you’re a hobbyist, an artist, or a professional manufacturer, this innovative technology is transforming the way we work with metals. In this comprehensive guide, we’ll explore everything you need to know about laser cutter metal systems, their applications, benefits, and how to choose the right one for your needs.

What Is a Laser Cutter Metal?

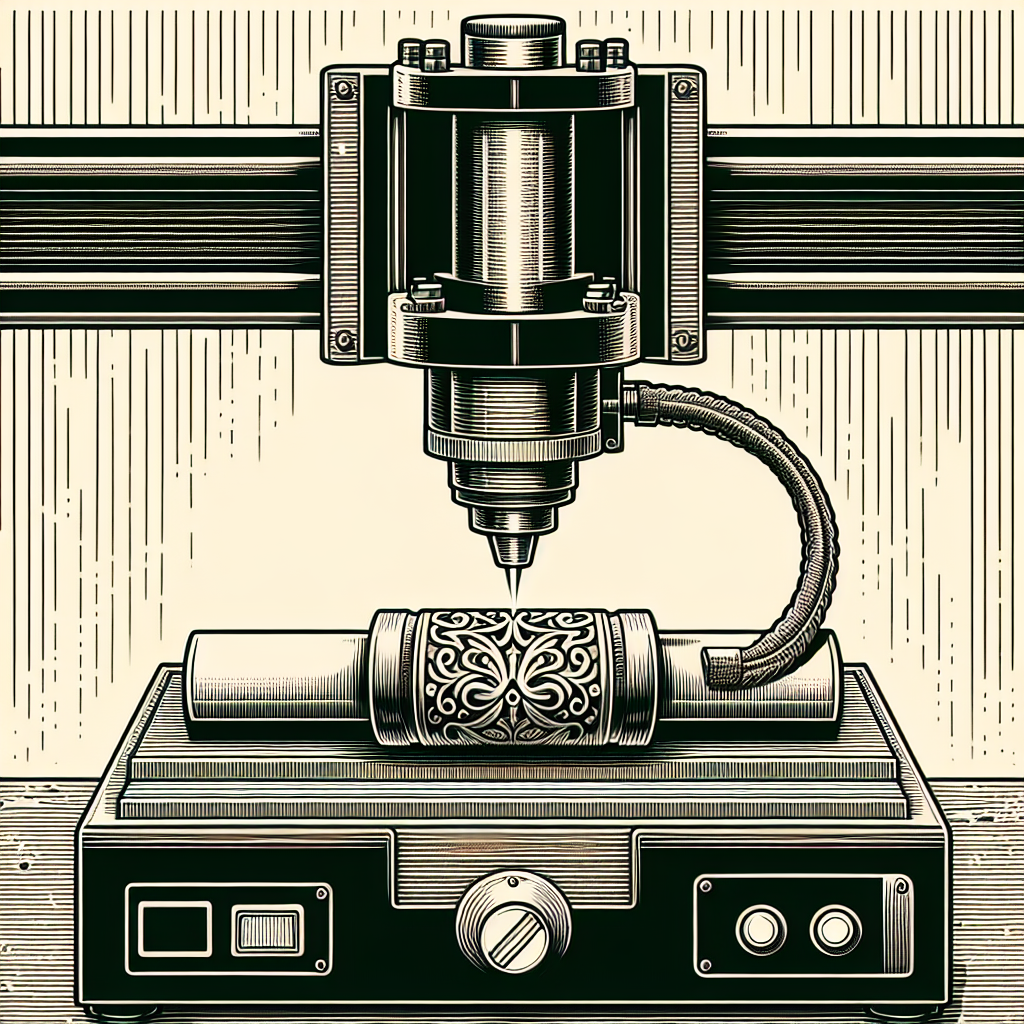

A laser cutter metal is a machine designed to cut and engrave various types of metal with exceptional precision. Unlike traditional cutting methods that rely on mechanical tools, laser cutters use focused light beams to melt, burn, or vaporize material. This process results in clean, precise cuts with minimal material waste.

These systems are highly versatile and can handle a wide range of materials, including stainless steel, aluminum, mild steel, titanium, and even exotic metals like inconel. The ability to cut intricate designs and patterns makes them indispensable for industries ranging from automotive manufacturing to jewelry design.

How Does a Laser Cutter Metal Work?

The operation of a laser cutter metal involves several key components:

- Laser Source: The laser generates a highly focused beam of light, typically using CO₂ or fiber laser technology.

- Focusing Optics: Lenses concentrate the laser beam to a pinpoint, creating extreme heat that melts or vaporizes the metal.

- Worktable: This is where the metal material is placed and secured during cutting. Most systems include clamps or vacuum tables to ensure stability.

- Software Control: Advanced software is used to design patterns, control the laser’s path, and optimize parameters for different materials.

The process begins with designing the desired cut or engraving pattern using specialized software. This software then translates the design into instructions for the laser cutter metal, controlling the beam’s intensity, speed, and focus. The result is a highly accurate and repeatable cutting process that can handle even the most complex designs.

Why Choose a Laser Cutter Metal?

There are several reasons why businesses and individuals are turning to laser cutter metal systems:

- Precision: Lasers produce cuts with unmatched accuracy, ensuring consistent results even for intricate designs.

- Speed: Compared to traditional methods, laser cutting is much faster, reducing production time and increasing efficiency.

- Versatility: A single machine can handle a wide range of materials and thicknesses, making it a cost-effective investment.

- Minimal Waste: The focused beam minimizes material waste, reducing costs and environmental impact.

- Engraving Capabilities: In addition to cutting, laser systems can engrave detailed patterns and text onto metal surfaces.

These benefits make laser cutter metal systems ideal for industries where precision and efficiency are critical. Whether you’re producing custom parts, creating decorative items, or manufacturing large-scale components, a laser cutter metal is a powerful tool that can elevate your work.

Applications of Laser Cutter Metal

The applications of laser cutter metal systems are vast and varied. Here are some of the most common uses:

- Automotive Industry: Cutting and engraving parts for cars, trucks, and motorcycles.

- Aerospace: Precision cutting of lightweight metals used in aircraft and spacecraft components.

- Electronics: Engraving serial numbers, logos, or other markings on metal components.

- Medical Devices: Creating custom parts for surgical instruments and implantable devices.

- Jewelry Making: Cutting and engraving intricate designs in precious metals like gold, silver, and platinum.

- Fabrication Services: Offering custom cutting services to other businesses that don’t have their own laser equipment.

The ability to work with such a wide range of materials and industries makes laser cutter metal systems an invaluable tool for modern manufacturing and craftsmanship.

How to Choose the Right Laser Cutter Metal

Selecting the right laser cutter metal system depends on several factors, including your specific needs, budget, and the types of materials you’ll be working with. Here are some key considerations:

- Laser Type: There are two main types of lasers used in metal cutting: CO₂ and fiber. Fiber lasers are generally more efficient and suitable for thicker metals, while CO₂ lasers are better for thinner materials.

- Cutting Capacity: Consider the maximum thickness of metal you’ll be cutting. Most systems specify their cutting capacity based on material type and thickness.

- Software Compatibility: Ensure the system is equipped with user-friendly software that can handle your design needs, including CAD integration for complex patterns.

- Budget: Laser cutter metal systems vary widely in price, so it’s important to balance features and performance with your budget.

If you’re unsure about which system is right for you, consult with experts or read reviews from other users in your industry. This will help you make an informed decision and select a machine that meets your specific requirements.

Tips for Getting the Most Out of Your Laser Cutter Metal

To maximize the performance and longevity of your laser cutter metal, follow these tips:

- Calibrate Regularly: Proper calibration ensures accurate cuts and prevents damage to both the machine and materials.

- Maintain Cleanliness: Keep the work area and optics clean to avoid dust buildup, which can reduce laser efficiency.

- Use Protective Gear: Always wear safety glasses and gloves when operating or near the machine, as the laser beam produces extreme heat.

- Experiment with Settings: Don’t be afraid to adjust cutting parameters like power, speed, and focus distance to achieve optimal results for different materials.

By taking care of your laser cutter metal and understanding its capabilities, you can unlock its full potential and create high-quality products with ease.

Frequently Asked Questions About Laser Cutter Metal

1. Can a laser cutter metal cut all types of metals?

While most laser cutter metal systems can handle common metals like steel and aluminum, some exotic materials may require specialized equipment or settings.

2. How thick can a laser cutter metal cut?

The cutting capacity varies by machine, but many systems can handle metals up to several inches thick, depending on the type of laser used.

3. Is a laser cutter metal safe to use?

Yes, when operated properly and with appropriate safety precautions in place. Always follow the manufacturer’s guidelines for safe operation.

4. Can I engrave text or logos on metals using a laser cutter metal?

Absolutely! Laser systems are excellent for creating detailed engravings, including text, patterns, and logos.

5. What’s the difference between CO₂ and fiber lasers?

CO₂ lasers are typically used for thinner materials and non-metallic surfaces, while fiber lasers offer higher efficiency and better performance with metals, especially thicker ones.

Conclusion

A laser cutter metal is more than just a tool; it’s a game-changer for anyone working with metals. Its precision, versatility, and efficiency make it an essential addition to any workshop or manufacturing facility. Whether you’re cutting intricate designs for jewelry or producing large-scale components for industry, this technology is sure to elevate your work to new heights.

If you’re ready to take the plunge into the world of laser cutting, consider exploring options like to find the perfect system for your needs. With a little research and planning, you’ll be well on your way to achieving professional-grade results in no time.

So why wait? Embrace the future of metalworking with a laser cutter metal and unlock your creative potential today!