The Industrial Laser Cutter: A Comprehensive Guide

Laser cutting technology has revolutionized modern manufacturing, offering precision and efficiency unmatched by traditional methods. Among the many tools available, the industrial laser cutter stands out as a versatile and powerful solution for various applications. Whether you’re working in metal fabrication, woodworking, or electronics, this machine can handle complex designs with ease. In this article, we’ll explore what an industrial laser cutter is, its advantages, how it works, and why it’s becoming a must-have tool in workshops worldwide. We’ll also address common questions to help you decide if this machine is right for your needs.

What Is an Industrial Laser Cutter?

An industrial laser cutter is a precision tool that uses a focused beam of light to cut, engrave, or mark materials with extreme accuracy. Unlike traditional cutting methods, which rely on mechanical blades, laser cutting uses heat generated by the laser to melt, burn, or vaporize material. This process ensures cleaner cuts and reduces the risk of warping or damaging the workpiece.

These machines are often used in industries such as automotive manufacturing, aerospace, electronics, and jewelry making. They can handle a wide range of materials, including metals like steel, aluminum, and stainless steel, as well as non-metals like wood, plastic, and glass.

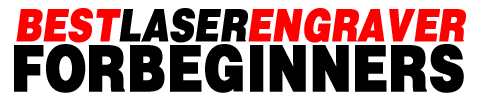

How Does an Industrial Laser Cutter Work?

The operation of an industrial laser cutter involves several key components:

- Laser Source: The heart of the machine is the laser source, which generates a high-powered beam of light. Common types include CO2 lasers for cutting thick materials and fiber lasers for high-speed operations.

- Focusing Lens: This component concentrates the laser beam to a pinpoint focus, ensuring precise cuts.

- Cutting Head: The head moves along X and Y axes to follow the programmed design or pattern.

- Material Handling: Most industrial laser cutters include a worktable or clamping system to secure the material during cutting.

The machine uses software to translate designs into instructions for the laser head. This allows operators to create intricate patterns and shapes with ease, even on large-scale projects.

Advantages of Using an Industrial Laser Cutter

There are numerous benefits to using an industrial laser cutter over traditional cutting methods:

- Precision: Laser cutters offer unmatched accuracy, producing clean edges with minimal material waste.

- Speed: Modern machines can process materials at high speeds, reducing production time and increasing efficiency.

- Versatility: They can handle a wide range of materials and thicknesses, making them suitable for diverse applications.

- Cost-Effective: Reduced material waste and faster processing times lower overall production costs.

These advantages make industrial laser cutters ideal for businesses looking to improve their manufacturing processes while maintaining high-quality standards.

Applications of an Industrial Laser Cutter

The versatility of the industrial laser cutter makes it suitable for a wide range of applications:

- Metal Fabrication: Cutting, engraving, and marking metals like steel, aluminum, and stainless steel.

- Woodworking: Creating intricate designs, joints, and patterns in wood products.

- Plastics Processing: Shaping acrylic, PVC, and other plastics with precision.

- Jewelry Making: Engraving details on precious metals and gemstones.

- Electronics: Cutting circuit boards and marking components with high accuracy.

These applications demonstrate the machine’s ability to adapt to various industries, making it a valuable investment for businesses of all sizes.

Frequently Asked Questions About Industrial Laser Cutters

If you’re considering purchasing an industrial laser cutter, you may have several questions. Here are some common ones:

- 1. How much does an industrial laser cutter cost?

- 2. What materials can an industrial laser cutter handle?

- 3. How easy is it to learn how to use an industrial laser cutter?

- 4. Can I upgrade my existing machine to include laser cutting capabilities?

The cost varies depending on the machine’s size, power, and features. Entry-level models can start around $50,000, while high-end systems may exceed $200,000.

Most machines can cut metals, plastics, wood, and glass. However, the specific material compatibility depends on the type of laser used (e.g., CO2 vs. fiber).

With proper training, operators can master the machine in a short time. Many systems come with user-friendly software that simplifies the design and cutting process.

In some cases, yes. Adding a laser cutting head or upgrading existing components can extend your machine’s functionality.

Why Invest in an Industrial Laser Cutter?

If you’re looking to enhance your manufacturing capabilities, an industrial laser cutter offers several compelling reasons to invest:

- Improved Efficiency: Faster processing times reduce downtime and increase productivity.

- Better Quality: Precision cuts result in higher-quality products with fewer defects.

- Versatility: The ability to work with multiple materials and applications makes it a flexible addition to your workshop.

- Returns on Investment: While the initial cost may be high, long-term savings from reduced waste and increased efficiency make it a worthwhile investment.

In conclusion, an industrial laser cutter is a powerful tool that can transform your manufacturing processes. Whether you’re working in metal fabrication, woodworking, or another industry, this machine offers precision, versatility, and cost-effectiveness that can give your business a competitive edge. If you have any further questions or are ready to take the plunge, consider exploring options like the to find the perfect solution for your needs.