Exploring the Capabilities of a Laser Wood Engraver Machine

Laser wood engraving machines have revolutionized the way we create intricate designs on wooden surfaces. These advanced tools combine precision, efficiency, and creativity to produce detailed engravings that were once impossible with traditional methods. If you’re curious about how these machines work, their applications, and why they are becoming increasingly popular, this article will provide you with a comprehensive understanding of the . Let’s dive in!

What is a Laser Wood Engraver Machine?

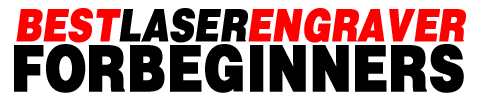

A laser wood engraver machine uses a focused beam of light to etch or cut designs into wooden surfaces. Unlike traditional engraving tools, which rely on mechanical cutting, laser engravers use heat to remove material, resulting in cleaner and more precise engravings. The process involves directing the laser beam across the surface of the wood, controlled by computer software that dictates the design’s path.

The machine typically consists of a laser head, a control panel, and a work area where the wood is placed. The laser emits pulses of light at a specific wavelength, which vaporizes or chars the wood to create the desired pattern. This method allows for intricate details and complex designs that are difficult to achieve manually.

Why choose a laser wood engraver machine?

- High precision and accuracy in design execution

- Capability to handle both small and large-scale projects

- Minimal material waste compared to traditional methods

- Ability to create custom designs quickly and efficiently

How Does a Laser Wood Engraver Machine Work?

To understand the functionality of a laser wood engraver machine, let’s break it down into its key components:

- Laser Source: The heart of the machine is the laser source, which generates the beam of light used for engraving. Different types of lasers are available, with CO2 being the most common for wood engraving due to its effectiveness in cutting and etching.

- Focusing Optics: These components direct the laser beam to a precise point on the surface of the wood, ensuring that the design is executed accurately.

- Control System: The machine’s control panel or software interface allows users to input designs, adjust settings, and execute the engraving process. Advanced systems offer features like speed control, power adjustment, and design preview.

- Work Area: This is where the wood piece is placed for engraving. The work area can vary in size depending on the machine’s specifications, accommodating both small items like wooden tags and large panels for furniture or signage.

The engraving process begins with designing the pattern using computer-aided design (CAD) software. Once the design is ready, it is sent to the laser machine, which converts the digital file into precise movements of the laser beam. The machine then scans the surface of the wood, applying controlled pulses of light to create the desired engraving.

Applications of a Laser Wood Engraver Machine

Laser wood engraver machines are versatile tools with applications across multiple industries. Whether you’re a hobbyist, an artist, or a professional craftsman, these machines can enhance your creative projects in numerous ways. Here are some common uses:

- Furniture Making: Add custom designs, patterns, and logos to furniture pieces such as tables, chairs, and cabinets.

- Signage Production:

- Crafts and Decorations:

- Artistic Expression:

Create decorative signs for businesses, homes, or public spaces with intricate lettering and graphics.

Engrave wooden items like picture frames, coasters, ornaments, and gifts with personalized messages or artwork.

Use the machine to bring your artistic vision to life by creating detailed wood sculptures, patterns, and murals.

What makes laser engraving stand out?

- The ability to create highly detailed designs without damaging the surrounding material

- Faster production times compared to manual engraving methods

- Reduced risk of human error in complex or repetitive patterns

Advantages of Using a Laser Wood Engraver Machine

Beyond its versatility, the laser wood engraver machine offers several advantages that make it an ideal choice for both small-scale and large-scale projects:

- Precision:

- Speed:

- Customization:

- Consistency: Laser engraving produces uniform results, ensuring that each piece is identical in quality and design.

The laser beam’s accuracy ensures that even the most intricate designs are executed flawlessly.

With modern machines capable of high-speed engraving, you can complete projects in a fraction of the time it would take manually.

Design software allows for unlimited creativity, enabling users to create unique patterns and customize every aspect of their work.

Is laser engraving safe?

While the process involves high-powered lasers, these machines are designed with safety features to protect operators. Proper training and adherence to safety guidelines ensure a secure working environment.

Maintenance and Care for Your Laser Wood Engraver Machine

To keep your laser wood engraver machine running smoothly, regular maintenance is essential. Here are some tips:

- Cleanliness:

- Lubrication:

- Software Updates: Keep your machine’s software up to date to benefit from the latest features and improvements in engraving accuracy and efficiency.

Dust and debris can accumulate on the machine’s optics and work area, affecting performance. Regular cleaning with a soft cloth or compressed air will help maintain optimal functionality.

Moving parts such as gantry systems and motors should be lubricated periodically to ensure smooth operation and extend the machine’s lifespan.

How often should you service your laser wood engraver machine?

A general rule of thumb is to perform routine maintenance every 100 hours of use or monthly, depending on usage frequency. This ensures that the machine remains in peak condition and minimizes downtime due to mechanical issues.

Frequently Asked Questions About Laser Wood Engraver Machines

If you’re new to laser wood engraving, you might have several questions about these machines. Here are some commonly asked questions:

- What types of wood can I use with a laser engraver?**

- Can I engrave on other materials besides wood?**

- How much does a laser wood engraver machine cost?**

- Is laser engraving suitable for commercial use?**

Laser engravers work best with untreated softwoods and hardwoods. Avoid using treated or painted wood, as the chemicals in these materials can produce harmful fumes when exposed to the laser beam.

Yes! Laser engravers are compatible with a variety of materials, including acrylic, glass, metal, and stone. The choice of material depends on the type of laser and its wavelength.

Pricing varies depending on the machine’s size, power, and features. Entry-level models for hobbyists can start around $500, while industrial-grade machines can range from $10,000 to $50,000 or more.

Absolutely! Many businesses rely on laser engravers for mass production of customized products. The machines’ efficiency and precision make them ideal for both small-scale crafting and large-scale manufacturing.

Conclusion

Laser wood engraver machines have become an indispensable tool for anyone looking to create detailed, custom designs on wooden surfaces. With their precision, versatility, and efficiency, these machines are transforming the way we approach woodworking projects. Whether you’re a hobbyist or a professional craftsman, investing in a laser wood engraver machine can elevate your work to new heights.

If you’re ready to take your woodworking skills to the next level, consider exploring the various options available on the market. Remember to choose a machine that aligns with your project needs and budget for optimal performance and satisfaction.